This year marks our 80th anniversary. We’re celebrating by going back in time, to trace the history of the modern-day backpack, a history slightly older than we are.

Humans have been carrying loads around on their backs since time immemorial. But it hasn’t always been easy. Years ago, hikers struggled under cumbersome, ill-fitting packs. This made the hours spent traipsing through the woods miserable. Over time, pack technology has gotten better. Let’s take a look.

1878: Merriam Knapsack

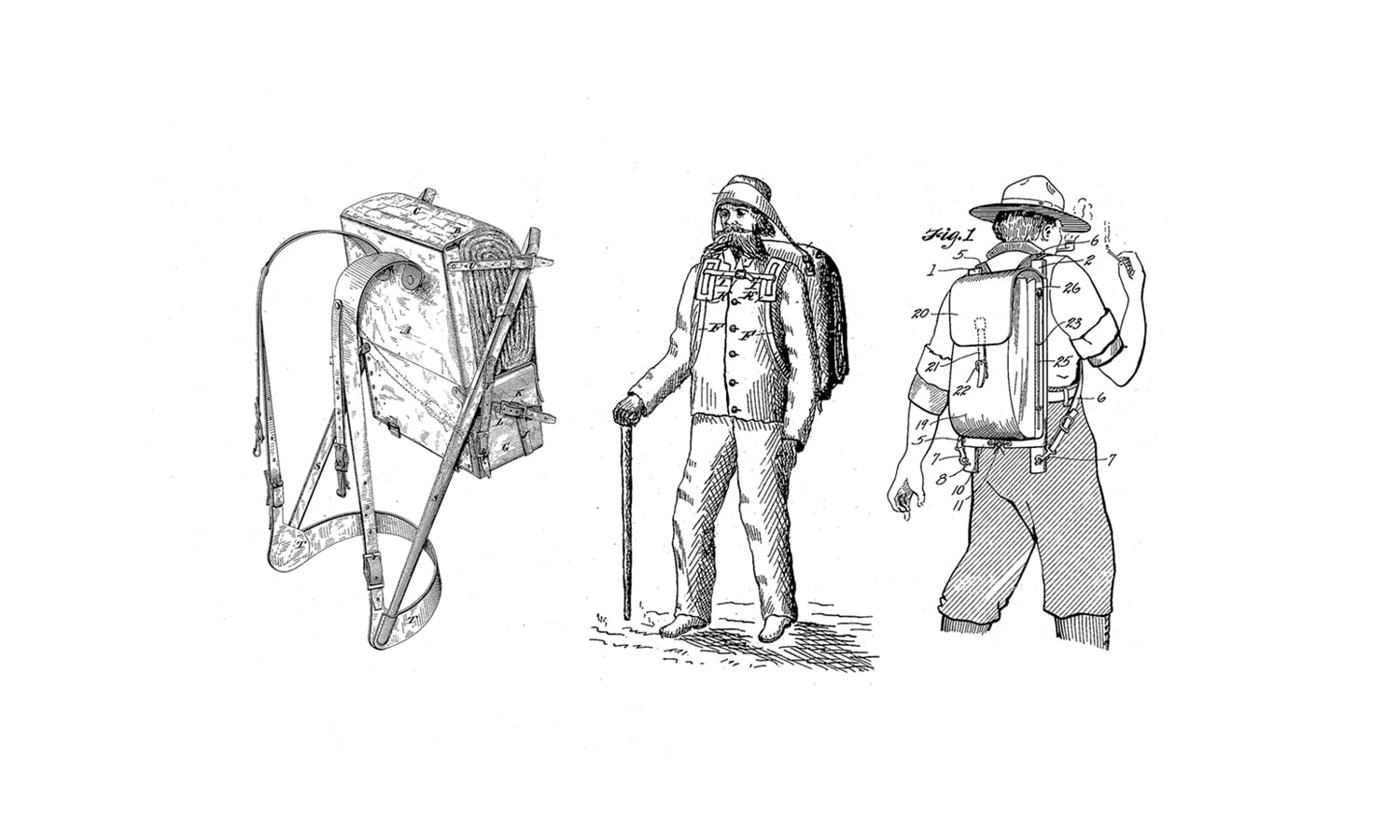

Before there were backpacking packs there were knapsacks, which were packs with shoulder straps that lacked any structure. Henry Merriam submitted a patent in 1877 (patented the following year) for a pack for the United States Army that used sheet metal to rig the bag away from the wearer’s body. Merriam wrote the that the pack helped by, “reducing the number of separate equipments, lessening the weight to be carried, and at the same time disposing it more uniformly, and leaving the body of the soldier freer and less hampered by straps and other fastenings.” It ended up being discarded because it simply was too uncomfortable.

1882: Duluth Pack

Camille Poirier of Duluth stepped up in 1882 to try something different. Poirier wanted to make sure his customers could carry a pack and portage a canoe at the same time, leading him to innovate a pack that sat lower on the wearer’s back and featured a head strap. This pack consisted of a large, durable canvas bag secured by straps and buckles. It had a square shape, made to fit easily into the bottom of the canoe. It was so loved, bags of a similar nature are still in production today.

1904: First Use of the Word

Near the turn of the century the noun “back-pack” started circulating. It took another eight years to become a verb (i.e., backpacked or backpacking).

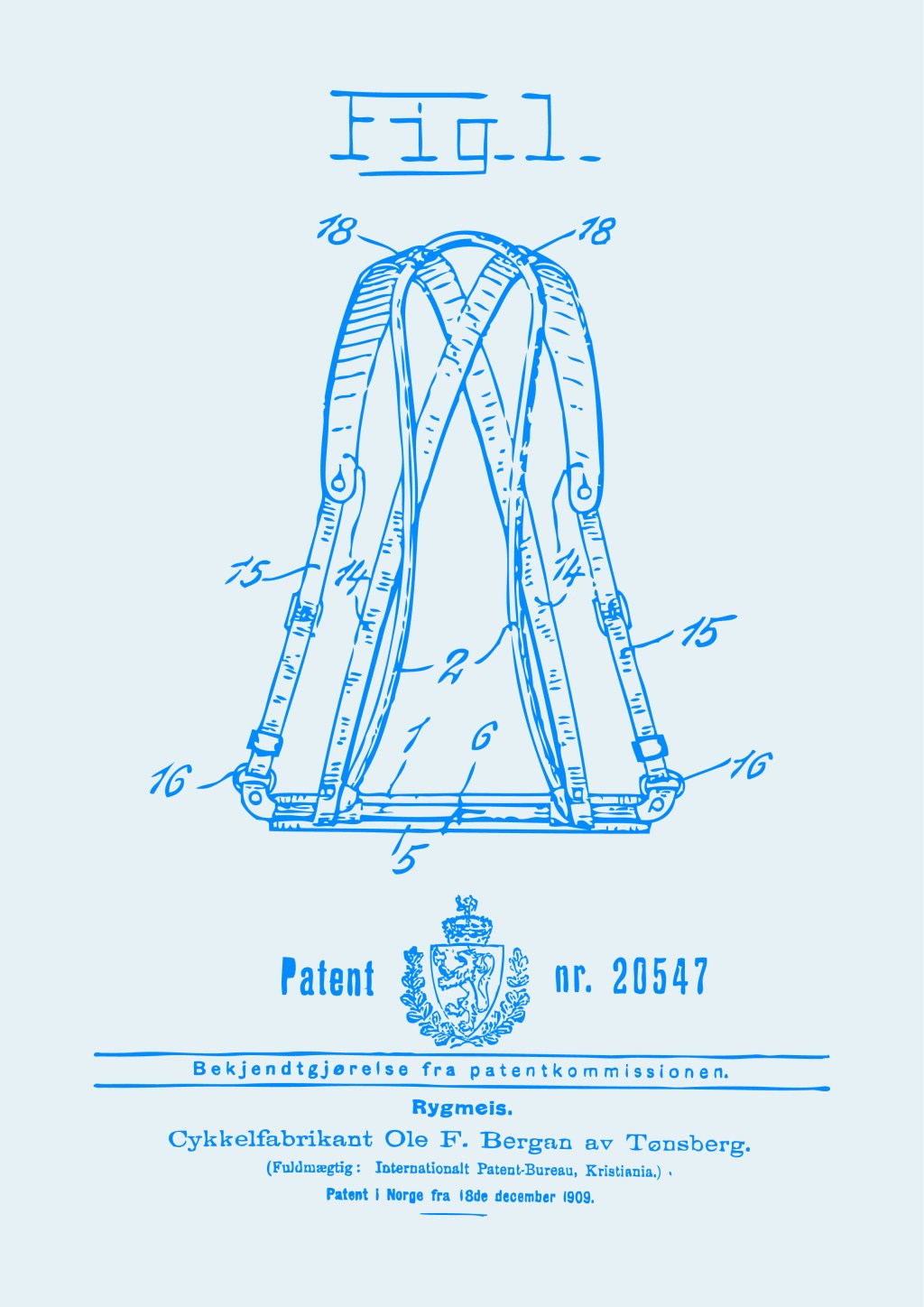

1908: Bergans of Norway Rucksack

Photo courtesy of Bergans of Norway.

Ole F. Bergan was returning home from a hunting trip when he decided enough was enough, he was going to combine the traditional Norwegian wooden frame with the soft material of a sack. He soon realized he needed to replace the birch he was using with light tubular steel that followed the shape of the back. His patent lasted for 25 years, during which time his packs traveled across the globe.

1924: Trapper Nelson Pack

This was the first-ever mass-produced external-frame pack. Nelson iterated on Inuit-made stick-and-sealskin backpacks that he first saw while visiting Alaska in 1920. This pack’s revolutionary design featured a stabilizing wooden pack frame with canvas bands that cushioned the load—a far cry from the bulky Duluth pack. A canvas bag was attached to the wooden frame with steel pins, so the wearer could detach the bag easily. The pack remained popular for years, even appearing in the first REI catalog in 1939. It came in three sizes, the largest costing $7.50, complete with a canvas bag. It remained the leading pack sold by the co-op through the ’50s.

1938: Cunningham Zippered Backpack

Up until 1938, straps and buckles were the way that packs closed. Gerry Cunningham changed the game by creating a backpack with two zippered sections. He was able to keep his load lighter and within reach for his primary use—rock climbing.

1950: Fjällräven Wooden Pack

In 1950, Åke Nordin, the founder of Fjällräven, was trekking in the mountains with a good friend and got sick of carrying his gear low and far from his back. Soon after returning home, he sat down at his mother’s treadle sewing machine and sewed a cotton bag. He next fashioned a wooden frame that would keep the load high and close to his back, and then fastened the bag to the frame with leather straps. This pack is what inspired Nordin to found his now-famous company.

1952: Kelty Backpack

Dick and Nena Kelty began handcrafting external-frame backpacks that brought the pack into the modern era. Using parachute fabric, buckles and other items leftover from World War II, the pair transformed the industry. Dick hand-formed and welded the pack frames while Nina sewed each pack. Theirs were the first packs to use aircraft aluminum, contoured frames, padded shoulder straps and waistbelts—although the waistbelt did not transfer pack load to the wearer’s hips until a few years later.

Kelty family hiking in 1957. PC: Kelty.

1967: Lowe Internal Frame

Greg Lowe, founder of Lowepro, created the first internal-frame backpack in his garage in Colorado. Frameless packs were too small to carry large loads and external packs were unbalanced on technical terrain. This pack had a frame stiff enough to transfer the load to the hipbelt, but flexible enough to contour to the shape of the wearer’s body. Lowe added a sternum strap and side compression straps, making this the first backpack that most closely resembles modern-day packs.

1970: Kelty Quick-Release Hipbelt

The Keltys continued to innovate in pack design. Dick Kelty designed and produced the first quick-release hipbelt buckle for a pack. It was made of stainless steel, and this sturdy buckle helped secure the pack tightly around the waist. This development allowed the weight of the pack to be transferred to the wearer’s hips, a given in modern-day pack design.

1979: Lowe Alpine First Women’s Pack

Lowe Alpine realized that their big packs didn’t fit smaller bodies. They were filling the void with custom packs featuring narrower shoulder pads, built on demand, but wanted to scale-up the operation. In 1979, Lowe Alpine started making their big packs adjustable for smaller people. By 1981, they had a full line called the Nanda Devi Series, offering options for female backpackers.

1984: Deuter Aircomfort

Photo courtesy of Deuter.

After years of sweating while wearing traditional packs, Deuter patented the idea of a mesh backing in 1984. The mesh created a ventilated space between the wearer’s back and the backpack, allowing cooling airflow to help keep hikers comfy on the trail. Soon other manufacturers took the idea and ran with it, innovating many different types of pack ventilation.

1989: CamelBak Hydration Pack

Micheal Eidson, a paramedic, was trying to figure out how to carry enough water for a hot Texas 100-mile bike ride. He finally rigged a system with an IV bag and a surgical tubing straw. The whole thing was housed in a tube sock sewn to his jersey. A few years later, CamelBak was on the market, and the history of backpacking hasn’t been the same.

1998: GoLite Breeze Pack

Demetri and Kim Coupounas were sick of hauling heavy gear over long distances. That’s why they founded GoLite, now My Trail Company. The first pack they introduced, the Breeze, had no hipbelt or framesheet and was the first pack to use lightweight and super strong Dyneema®. The innovation of this pack marked a shift in which the outdoor industry began using lighter materials for lighter gear.

2003: REI ActivMotion Suspension

The ActivMotion hipbelt helped transfer the pack load from the small of the wearer’s back to their hips. It was a mainstay of the REI packs for many years. This hipbelt was fashioned in such a way that when a person’s hips moved up and down, a rod and extension compensated for the movement. This helped to stabilize the load and minimize side-to-side swaying—a game changer for our packs.

2005: Osprey Custom Molding Hipbelt Technology

What’s better than a hipbelt that boosts stability on long treks? A hipbelt that molds to your body! Osprey made big strides in 2005, transforming the market by allowing backpackers to mold their hipbelts to their unique anatomy—allowing for a more comfortable fit.

Photo courtesy of Osprey.

2018: REI Uses Recycled Fabric for Pack Line

Based on an environmental life-cycle assessment research project with Duke University, the REI team found that using recycled fabrics makes the biggest positive impact on the environmental footprint of a pack. Fabric accounts for 81 percent of a pack’s global-warming potential, 48 percent of its water consumption, 72 percent of its energy consumption, and 75 percent of its eutrophication (a type of water pollution that causes damaging algae overgrowth and oxygen depletion). Our team worked directly with the textile mill to create custom fabrics made from 100% recycled nylon that still meet our stringent durability requirements. The development of the REI Co-op Traverse pack line was a huge step forward for us and the outdoor industry.