The late Carsten von Birckhahn didn’t find his inspiration behind a desk. While working as brand manager for climbing gear manufacturer Edelrid, he often left his business cards behind and headed to South America. There, on the towering granite walls of Patagonia, where von Birckhahn put up impressive ascents alongside marquee names likes Tommy Caldwell and Colin Haley, the gear innovator would often ask his peers what was missing from their climbing kits.

The answers varied widely, but he noticed a pattern: Climbers wanted high-performing gear that was also eco-friendly. According to Blair Williams, vice president of Edelrid North America, Von Birckhahn used these insights to help shape Edelrid’s sustainability efforts through technology and product development.

At Edelrid, von Birckhahn helped develop a process to make new climbing ropes using leftover yarns and other rope remnants.

Climb green

Sustainability wasn’t novel to Edelrid. In 2008, the company became the first climbing gear manufacturer to partner with bluesign® technologies. The independent Swiss firm works with companies in the textile industry to make the product and materials manufacturing process more environmentally sustainable. Bluesign partners commit to the responsible use of resources and to improve their chemicals management practices.

When it came to an eco-friendlier rope, Edelrid’s team first looked at the yarns used to make a climbing rope.

“Climbing ropes are consumable products made with virgin polyamide yarns, a product derived from petroleum,” explains Williams. “Petroleum is a non-renewable resource, and the extraction and refinement of this limited resource have its own immense environmental impact.”

Edelrid product designers researched the problem for more than two years before introducing the Boa Eco 9.8 mm Non-Dry Rope in 2016.

The Boa Eco’s sheath uses high-quality yarns left over from the manufacturing process. This alternative production reuses 22,370 miles of yarn annually that otherwise would have headed to a landfill, according to the company. The bluesign® product also uses less water, energy, carbon emissions as well as fewer chemicals.

And since the ropes are made from different batches of leftover yarn, each rope has a unique colorful pattern.

PFC-free rope

The sheath of the rope is only one element of the production process. A rope’s waterproof coating is another. Perfluorinated chemicals, or PFCs, are frequently used in outdoor equipment as well as other consumer products. The chemicals help repel oil, grease and water. Rope makers often use PFCs in dry treatments to help prevent ropes from absorbing water. But the chemicals don’t break down easily and they persist in the environment, causing significant concern across the outdoor industry and beyond.

Von Birckhahn and his colleagues knew a more sustainable rope would have to ditch PFCs. The problem: finding an alternative that still met international safety standards for water repellency.

The company threw itself at the challenge. After two years of research and development, their efforts paid off in 2018 when Edelrid introduced the Swift Eco Dry 8.9 mm single rope. By incorporating a wax-based coating into the sheath and core, the team was able to develop the first climbing rope made without PFCs to meet water-repellent standards set by the International Mountaineering and Climbing Federation (UIAA).

‘A massive undertaking’

Williams says the company knew it could do still more to reduce its environmental footprint.

“It became clear to us that the best way forward would be to learn how to use recycled materials versus creating new materials,” he says. Raw materials and waste disposal account for the bulk of a rope’s carbon footprint.

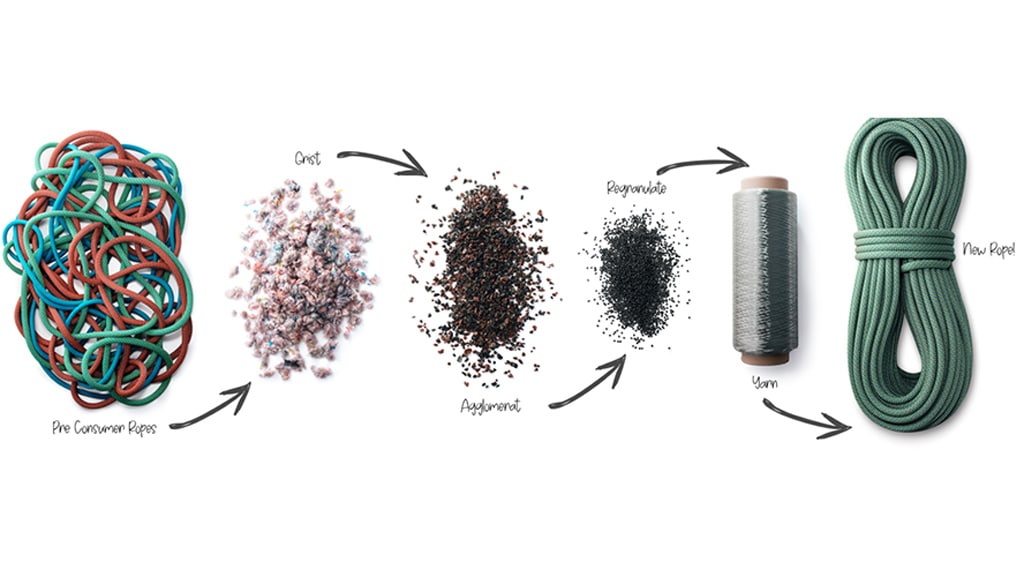

So, the team plucked brand-new, unused ropes and rope pieces that ended up on the factory floor. This included ropes with irregularities, pre-production samples or offcuts. Then, they got to work figuring out how to recycle those old ropes into new ones.

But recycling an old rope into a new one isn’t like recycling other plastics. Doing so presents unique challenges. For instance, while outdoor companies now make shirts, backpacks and shoes from recycled plastics, no one’s life hangs from a shirt. A climbing rope must not fail. (Climbing ropes also must adhere to safety standards).

Edelrid secured a federal grant in Germany to tackle the challenge. The company also collaborated with several universities to develop new technology and process.

“It was a massive undertaking,” Williams says.

Typically, a brand purchases virgin yarns in thin strands, ready to use. In this case, Edelrid product engineers had to start with a braided rope with its sheath and core intact.

First, the team deconstructed the ropes and returned them to their basic polyamide structures. From there, they melted them down and extruded them into yarns. In short, Edelrid designers ultimately figured out how to turn a bunch of unused ropes into a new climbing rope, fully rated and ready for the wall.

The proof-of-concept rope (which used 100% recycled climbing ropes) passed the UIAA Single Rope test in 2018. It would take two more years of work for Edelrid to bring a recycled rope to market.

The result? The NEO 3R, a dynamic 9.8 mm rope that uses 50% recycled materials from other ropes. (The rope is expected to arrive in select REI stories in late 2021).

Making ropes out of recycled ropes isn’t cheap. Because of the complex process and lower volumes, using recycled yarn costs roughly three times as much as using virgin yarn, according to the company. So, to keep the price down for consumers, Edelrid designers used 50% recycled pre-consumer ropes in the NEO 3R.

The goal is soon to be able to sell rope made completely out of old ropes. “The NEO 3R represents that first big step in achieving this goal, by showing that we now have the ability to recycle pre-consumer ropes into a new rope,” says Williams.

Von Birckhahn wouldn’t live to see the pinnacle of his work in the NEO 3R. He tragically passed away in a paragliding accident in 2017. But his legacy lives on as climbing to a more sustainable business never ends. There is always another pitch, and the challenge is what makes it interesting.

For more stories of brands doing good work, visit our Good Gear landing page.